While every product starts out with an idea, several different processes are involved in turning the idea into a user-friendly product. Without a well-planned development process, the best product idea will remain – just an idea.

Prototyping is a crucial step in turning your idea into a product. It gives you physical proof of your product’s feasibility and makes it easier to spot design flaws. Concept models can be hand-made or rapid prototyped.

This article will discuss rapid prototyping, the techniques involved in building prototypes, their use cases, the advantages of rapid prototyping, and necessary steps involved in building a prototype.

Do you have a physical product or mobile app idea you want to launch?

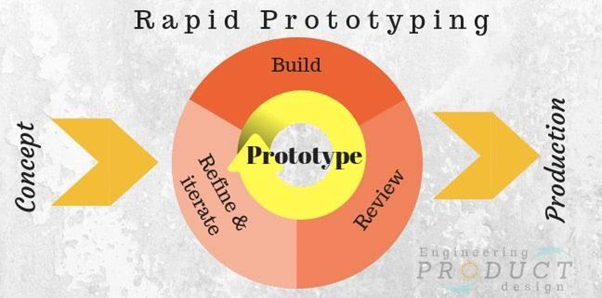

What is Rapid Prototyping?

Rapid prototyping describes the process of quickly building components without the use of expensive tooling and long lead-times. The processes can include additive prototyping (3D printing), subtractive prototyping (machining) and even low volume soft tool molding such as cast urethane molding.

Rapid prototyping is often defined as the speedy manufacturing of products with improved technical processes. As a result, rapid prototyping techniques have helped inventors, startups, and well established companies quickly innovate and develop new products at a much faster rate than was previously possible.

Is Rapid Prototyping the Same as 3D Printing?

Although the phrase has been used interchangeably with Rapid Prototyping and 3D Printing, they actually aren’t necessarily the same thing. It’s kind of like how a square is a rectangle but a rectangle isn’t necessarily a square. 3D printing or additive manufacturing is the process involved in making a physical object from a three-dimensional digital model, while rapid prototyping utilizes different, innovative technologies — CAD (Computer-aided design) files and processes such as 3D printing to achieve a cheaper, faster production process. Rapid prototyping can be used to describe multiple different prototyping processes including 3D printing (additive manufacturing), CNC machining (subtractive manufacturing), and soft tool mold manufacturing. It can also be used to describe the process of creating quick-hand built models out of various materials such as foam, and modifying and adapting existing components.

Types of Prototypes in Product Design

Prototypes of various forms are used, depending on the production stage. Each of these prototypes serves a unique purpose for the design team, who look to test for specific characteristics on their journey to the final product. Typically, the lower The four major types of prototypes used in product design are:

1. Feasibility Prototypes

Rapid prototyping companies use these prototypes early in the product development process to decide whether a product is feasible or not. They are used to validate a proof of concept and provide the qualification needed in later stages of the development.

2. Low Fidelity Prototypes

Fidelity in prototyping systems explains the degree of accuracy required from a prototype or 3D print. Therefore, low-fidelity prototypes don’t look exactly like the actual product but are used by the design team to showcase concept models of the product.

A low fidelity prototype smartphone

A low fidelity prototype is often a paper prototype with surface finishes that mimics the final product. While they are easier to create, low-fidelity prototyping is used early in the development cycle where user interaction is not allowed.

3. High Fidelity Prototypes

The other half of low fidelity prototyping yields high fidelity prototypes. These prototyping tools are used to create a prototype or a 3d print that is a true representation of the final product. In most cases, high-fidelity prototypes have a complex design and will take the same approach to the user interface as the final product.

A high fidelity prototype smartphone undergoing user testing

A high-fidelity prototype allows designers to render a realistic model of the product. They often have complex designs and are used by rapid prototyping companies for usability testing. Hence, they are used to get user feedback.

4. Live-Data Prototypes

The primary purpose of a live-data prototype is to prove that an idea (a feature, a design approach, a workflow) really works. Rather than create multiple iterations, rapid prototyping companies will create a live-data prototype to test for a specific set of functionalities.

As a result, usability testing is usually limited to the “live data” these prototypes are designed to collect. Such tests are typically based on invites, and the specific functionality to be tested is outlined.

Use Cases for a Prototype

Prototypes can be a valuable tool across all stages of the product development process. Some of the most common use cases for the procedure are;

1. Validating New Product Ideas or Concept Models

Prototypes are often used to validate concept models early in developing a product to determine the best concept model for the customers. Upon discovering the best concept model, the producer can meet the users’ needs and expectations even before production begins.

2. Testing New Features

Rapid prototyping can be used by a design team looking to test out new features or perform functionality testing. Rather than jump to mass production, the development team can create a low-fidelity prototype for users to test and validate.

In addition, developers can use this process to identify issues and pain points in the product and develop a proof of concept for rapid manufacturing.

3. Market Validation

A design team can use prototyping processes to achieve market validation from users even before a product is launched. A low volume can be produced and distributed to a select group of users who interact, test, and validate the product.

Upon market validation, mass production can commence. However, if there are negative feedbacks about the product, the final product can be worked on using user feedback. Market validation will give the design team a final product to continue production.

4. Getting Stakeholder Feedback

A prototype test is not only used to get users’ feedback but can also be used to get feedback and support from stakeholders. For example, a digital or paper prototype can be presented before the company’s stakeholders to encourage their involvement in the development cycle.

5. Assessing Product-Market Fit

Sharing your prototype with potential users is a great way to gather valuable feedback, carry out functionality testing, and evaluate your product-market fit. In addition, design teams can use prototype testing to see how well your product meets your target audience’s needs and identify growth opportunities.

Do you have a physical product or mobile app idea you want to launch?

Steps to Building a Prototype

Building a prototype is essential for companies looking to launch a new product or update an existing product design. The following steps should be applied in building product prototypes.

1. Idea

Starting with the idea or concept of a product helps to create a better product outflow and saves time. Before building the prototype, the design team should identify the basic functionalities to solve a pre-identified users’ problem.

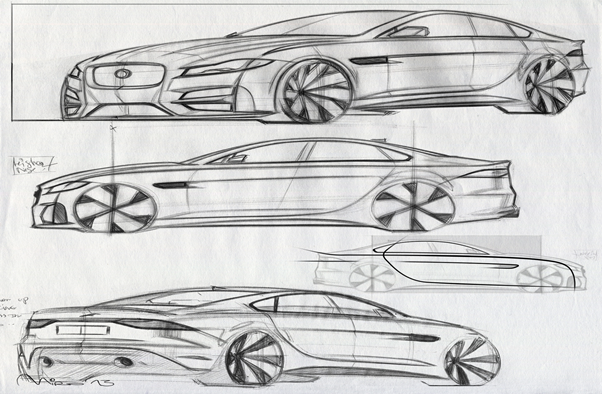

2. Create a Concept Sketch

Early in the production cycle, creating a concept sketch will be invaluable in building a prototype. First, draw your idea to enable you to imagine your prototype in more prominent detail. Concept models are mostly hand-drawn sketches, often referred to as paper prototypes.

Proof of concept for a jaguar

3. Develop a Digital Prototype

Using the paper prototypes, a design team can create digital prototypes of the product. Adobe xd, Autocad, Blender, and SketchUp are top-rated software programs used for design cad (Computer-Aided Designs).

Proof of concept for a jaguar using AR/VR

Converting paper prototypes to CAD files will be invaluable in creating multiple iterations of a design. These CAD files can also be converted into a 3D rendering or a 3D print to give you a multi-dimensional look at the product. Because of the technicality involved, creating a 3D print should be left for rapid manufacturing companies.

4. Create a Functional Prototype

A ready prototype should be created without compromising functionality. Prototyping processes help a design team to analyze the cost, feasibility, and marketability of the product. Then, the interactive prototype can undergo a closed-testing phase with limited users to get feedback and areas that can be improved before product launch.

A functional prototype of a jaguar

5. Incorporate Feedback and Finalize Your Product Design

This is the final step before the finished product is mass-produced. After integrating all necessary feedbacks, have a functional prototype that represents what the product will resemble. A manufacturer that offers 3D printing can help you cut costs both in the production and testing phases.

Types of Rapid Prototyping Techniques

While there are different prototyping techniques, they can be summarized into additive manufacturing and CNC tools.

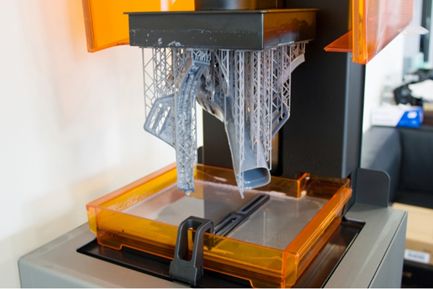

1. Additive Manufacturing (AM)

Additive manufacturing or AM is commonly known as industrial 3d production. Additive manufacturing involves the production of 3d models from CAD files. The major types of additive rapid tooling used by are;

I. Stereolithography SLA

Stereolithography SLA is an AM process used for creating solid patterns and products from CAD files. SLA is used for constructing solid plastic prototypes models that are weaved from a CAD-powered laser beam gun.

3D Printer – Stereolithography SLA

Stereolithography SLA is famous for having the highest resolution and accuracy among other types of rapid manufacturing. SLA parts also have the smoothest finishes. Through injection molding, the mass production of products with complicated shapes can be achieved.

II. Selective Laser Sintering SLS

Selective Laser Sintering SLS is an AM technique that involves laser sintering small particles of plastic, ceramic, or glass into a solid model using a high-power laser. Hence, SLS is ideal for creating complex geometries.

Selective layer sintering

Selective laser sintering SLS is the most common AM technique engineers, and manufacturers use for industrial 3d modeling. While this prototyping process may not yield results as smooth as Stereolithography SLA, SLS produces strong, functional models.

III. Direct Metal Laser Sintering DMLS

DMLS is a type of AM or 3D printing used in building rapid metal prototypes and production parts. This metal prototyping involves sintering each layer of sheet metal with a laser aimed onto a metallic powder bed.

3d printers – Direct Metal Laser Sintering DMLS

The process is repeated for each layer of sheet metal until the product model is completed. After that, the surface is brushed and heat-treated to relieve any stresses. As a result, products from metal prototyping achieve almost 100% denseness.

IV. Fused Deposition Modeling FDM

Fused Deposition Modeling (FDM) is an AM process used in building models by melting and extruding thermoplastic filament (injection molding). Fused deposition modeling is the cheapest and most commonly used form of 3D printing at the consumer level.

When compared with other plastic 3D printing processes, fused deposition modeling has the lowest resolution and accuracy. After injection molding, chemical and mechanical polishing can be used to attain finishes of a higher quality.

V. Binder Jetting

Binder jetting is a prototyping process used for making objects described by digital data such as a CAD file. The binder jetting process uses two materials; a powder-based material and a binder.

Schematic representation of binder jetting

An industrial printhead selectively deposits a binding agent (binder) onto a thin layer of powder particles. After that, the material to be bound is lowered on its build platform. Binder jetting is the fastest form of 3D printing for metal prototyping.

2. CNC Tools

Computer Numerical Control or CNC tools is used in prototyping and mass production. CNC machines can handle the entire product development process for cutting, boring, carving, machining, and grinding. CNC machines can be used to process plastics, soft metals, hard metals, wood, acrylic, stone, glass, and composites.

Unlike AM, CNC tools are more complicated to set up and operate. However, CNC machines are automated and used for faster production.

More complex CNC machines are required for tooling, handling, positioning, and processing in specific manufacturing processes. Because of the high cost of CNC machines, they are primarily used in large-scale production.

CNC Machines for cutting ceramic tiles

Advantages of Rapid Prototyping

While it is common knowledge that rapid manufacturing has helped companies get better products to market faster than their competition, what are the advantages of the process?

1. Save Cost and Time

With 3D printers, a company can avoid the cost and time involved in building models for functionality testing. With little cost and time, 3d printers can create different models until an ideal product model is found.

2. Communicate Ideas Effectively

While digital models offer great flexibility, physical models help design teams to easily share their concepts with colleagues, clients, and collaborators. In addition, when users interact with a 3d model rather than a digital interface design, they can give clear, actionable feedback.

And for every manufacturer, getting feedback and design tips through usability testing is crucial in understanding user needs and then refining and improving their designs.

3. Work Out Concepts Faster

Prototyping processes elevate initial ideas to low-risk concept explorations that look like real products in no time. It allows designers to go beyond virtual visualization, making it easier to understand the look and feel of the design and compare concepts side by side.

4. Design Iteratively and Instantly Incorporate Changes

Thanks to prototyping processes, companies can make multiple iterations of a product. Adjustments can easily be made to the digital prototype and reprinted with 3d printers upon receiving feedback and design tips.

5. Test Thoroughly and Minimize Design Flaws

In product development, flaws in a product can be expensive – the overheating of the Galaxy Note 7 cost Samsumg $17 billion in sales. Prototypes help a company carry out usability testing on multiple iterations of a product before the finished product is put on the market. So it’s critical not to rush or cut corners with the product design iteration and prototyping process.

In Summary

Prototyping processes have helped companies get better products to market faster than their competition. Manufacturers can now create prototypes within a day and carry out multiple iterations of design, form factor study, assembly and functionality testing. Understanding the advantages of rapid prototyping and knowing which process to use for different design projects will directly affect a product development company’s time to market and development cost.