What comes to mind at the mention of mass production? Do you ponder over the numerous attempts to develop working products? It is a marvel that through the years, entrepreneurs and companies have developed robust mass production systems, delivering delightful physical products to serve the ever-growing human population. It takes time to perfect product designs and define and actualize the physical features of consumer products. We owe this success to industrial design.

Let us look at the relevance of industrial design in the product development process and understand its evolution over time and the approaches designers use to enhance user experiences.

Do you have a physical product or mobile app idea you want to launch?

What is Industrial Design

We interact with different devices every day. Some bear some resemblance, while others have unique features defining them. Either way, these products undergo a rigorous design and testing phase before being released to the end-user. Any industrial design company understands that customer experiences come first. Appealing products attract more customers, and that means better revenues.

Industrial design is an approach that product designers, creative artists and other professional developers leverage to create innovative products. It involves a series of iterative actions to validate and actualize invention design. At every product development phase, the designer or architect focuses on the functionality, physical appearance, and manufacturability of the end product.

A well thought and executed product development cycle is beneficial in many ways. It doesn’t matter if you deal with an interior design project, social media platforms, consumer products, industrial parts or packaging. The designer needs to ensure they have a competitive advantage over entities offering similar products or services.

The beauty of industrial design is that companies can gradually improve the quality of products without compromising their technical capabilities and functionalities. The entire process combines creativity and scientific reasoning to reach actionable solutions. Of course, the balance between creativity and scientific knowledge depends on the product in question. When working on new consumer products, the designer evaluates the suitability of available materials and manufacturing processes. Issues like conformance with the company’s business strategy and consumer trends play critical roles at the design stage. The designer needs to consider these aspects when designing disruptive consumer products for mass production.

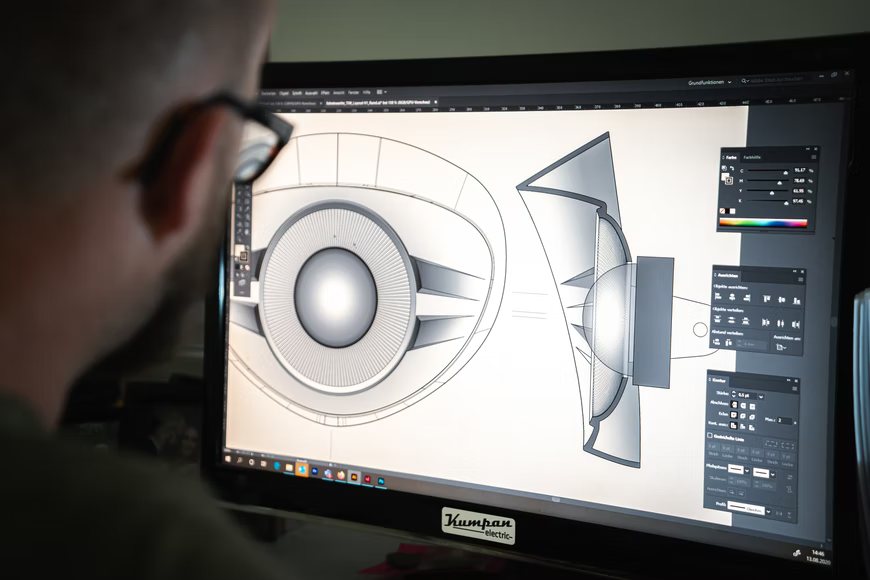

Manual design remains relevant in modern industrial production

Historical Overview of Industrial Design

Industrial design is an old discipline. It has been in existence since the early ages of industrialization and mechanization. Before industrial design, individual craftspersons were responsible for creating products to the satisfaction of their clients. Skilled individuals perfected a particular skill and passed it down to younger generations through apprenticeships. With the start of the industrial revolution, companies needed to adjust their processes and redefine production design.

Mass production was at the center of the first industrial revolution. Companies were obliged to create products to serve diverse consumer segments. The discipline was famous among German designers. It gradually expanded to several countries across Europe in the 20th century. In the beginning, designers like Behrens utilized industrial design to create unique building designs and electrical appliances for a growing middle class. The success of the pioneers in this field inspired other designers to implement it on diversified products. The expansion saw its adoption in the automotive, aviation, furniture and architectural sectors.

As time progressed, the discipline evolved. America, like the rest of the world, embraced industrial design. It was in response to the losses of the first world war. Industrial designers, artists and craftspersons formulated professional associations to improve professionalism and collaborations between experts. The Society of Industrial Designers and the American Institute of Designers are some of the bodies established to regulate the activities of the pioneers of industrial design in the US.

The industrial revolution has come a long way since the early ages of mechanization. Modern industries feature several automation technologies and advanced production processes. Consumer trends have equally changed. It means that industrialists are continuously adapting to change. The dynamic consumer trends require companies to be proactive when designing and testing new consumer products.

Industrial design is now applicable across industries. Designers utilize several digital tools that enhance the entire product development cycle. At the back of this are user-centric design approaches. They leverage prototype design to reduce turnaround times amid the stiff global competition.

Rapid prototyping is improving the quality of product design

Production in the 21st century has gone a notch higher. Unlike in the past, every production process is lean. Companies try to optimize product quality, minimize supply chain risks and develop sustainable products. That means companies are investing heavily in rapid prototyping, advanced production equipment and engaging highly-skilled product development teams. The ultimate goal is to leverage industrial design to create valuable, sustainable and durable products for their target markets.

Do you have a physical product or mobile app idea you want to launch?

The Design Process (Industrial Design Perspective)

Creating a new product requires time. No one wakes up with an idea, develops it and creates a working solution within a day. Product development is a creative process that involves research, modeling, prototyping and testing. Industrial designers consolidate data from different sources to create realistic product models using 3D software. It gets better. The prototyping and manufacturing processes leverage advanced technologies. Companies can mass-produce consumer products and iterate designs to suit specific market segments.

Using 3D software to optimize product designs

The industrial designer defines the form, features and functionality of a product. They explore the different production materials, ergonomic requirements and appropriate manufacturing processes to guarantee the success of consumer products. Therefore, industrial designers use different approaches to address product development. The schools of thought regarding industrial design include:

- Co-design

- Third-order design

- Fourth-order design

Third-order design

When using this approach, the designer seeks to strike a balance between production and market dynamics. The designer carries out market research to identify the needs of the consumers. They then compare the research results with the production capabilities of the company. Finally, they embark on the design of new products. The designer makes decisions that directly affect the scope of product development. For instance, the industrial designer has to understand how a packaging design affects customer attraction and retention. Beyond that, the designer needs to guarantee that the final product fits in the packaging and meets usability needs.

The customer indirectly influences the design process. In third-order design, the company or designer develops a prototype, a replica of the final product. The customer tests it and provides feedback to the designer. The industrial designer observes how consumers adapt to product features and refine product designs for an ultimate user experience.

Fourth-order design

Unlike the third-order design, this approach focuses on other aspects beyond product usability and market conditions. It explores wider aspects of consumer products. The designer considers socio-economic factors, sustainability and cultural preferences. The designer questions the value of the proposed consumer product and if it deserves to exist. The fourth-order design approach is human-centric and puts the end-user at the center of all design decisions.

Co-design

Product development teams are continuously innovating. There is a shift from traditional industrial design approaches. Co-design is a modern product development approach that requires the input of individuals with different skill-sets. It is a flexible design process and allows the small design teams to gather sufficient data to facilitate holistic product designs. In some cases, the design team involves a volunteer end-user in the design process. The volunteer becomes the primary point of reference. An example of a co-design is a team of industrial designers working on an assistive walking device for physically challenged customers. The team will work closely with the consumer, twitching product designs to the user preferences.

Studying Industrial Design

Industrial design continues to transform by the day. The design process focuses on delivering desirable consumer products. It means that the entire product development cycle requires the input of multi-skilled individuals. Institutions of higher learning offer different courses in industrial design. The institutions have design-focused programs that blend design strategies, design research, UI/UX design, graphic design and service design. Some institutions specialize in a particular design niche, while some offer courses with a mix of engineering, arts and design programs.

Industrial design courses are taught at undergraduate and graduate levels. Individuals can study these programs in universities or approved vocational colleges. Different entities accredit these programs to ensure the relevance of the curricula.

Studying a relevant industrial design program allows designers to systematically integrate product ideas and scientific knowledge to develop innovative solutions addressing pertinent consumer challenges.

In the modern age, multi-disciplinary experts work together to design new products. That means that all industrial designers require skills to enhance the product development process.

Final words

The impressive products we interact with daily are a result of well-executed design and development processes. These products (or services) are a result of industrial design. The discipline has been central since the inception of industrialization and mechanization. It keeps adapting to changes in technology and plays a pivotal role in reducing production costs while enhancing user experiences. Designers can adopt any of the design processes aforementioned to fulfill their product development goals. Individuals interested in improving their design skills can enroll in an industrial design skill to enhance their problem-solving skills and acquaint themselves with advanced product development approaches.