Product Development Company

Every product currently on the market started with an idea or a vision and has undergone a great deal of creativity, analysis, and strategy before it can be successfully commercialized. But with the right product development company the process can be straightford and efficient.

Here we’ll explore the product development process and how a product development company can help bring a new product from idea to reality.

What is Product Development?

Product development is the process of turning an idea into a real, functional product through the use of design, engineering, prototyping, and testing. It involves all the actions involved in creating a new product or improving an existing product for customers. Product development begins with a concept and continues until the product is ready to be manufactured and introduced to the market. The product development process can extend beyond the initial product launch to optimize the product based on market trends and customer feedback.

The Product Development Process

To launch a successful product, the development process has to include a team of well-trained experts in their various fields. The industrial designer forms a core component of that team, making contributions and recommendations along the way. As such, an industrial designer or an industrial design company should be involved in every step. Here’s an abridged version of the product development process.

- Get Feedback from Users

Communicating with the users is one of the earliest stages in the creation of a product. The journey of every product begins with identifying the problems faced by the end-users.

- Define the Problem

By interacting with the consumers, entrepreneurs can define the challenges the users face with the products they currently use.

- Analyze the Problems for Potential Solutions

By analyzing the users’ challenges, inventors and startups can determine if a new product is necessary or an improvement needs to be made to the current design.

- Build a Design Prototype

With an understanding of the problem that should be solved, and a detailed manufacturing specification, a design prototype should be created. Spending time analyzing the virtual prototype (product specification) before a physical prototype has been made will reduce the time and money spent prototyping a product.

- Test Your Solution

After the physical product, application, or software prototype has been created, the functionality of the product is tested. If the product does not meet the set functional requirements, then the product design process should be iterated. However, if the product does meet all functional requirements, then you can proceed to commercialization.

- Commercialization

This is the final stage of the development process in which the new product will be launched. Before the product launch, the product development team should identify the perfect marketing strategy for pitching the product to the public.

- Ongoing Iteration

After a product has been released into the market, enhancements, expansions, and changes will need to be made. While this can happen before the product is launched, getting frequent feedback from the users will help in improving the product.

Because of the complexity involved in product development, businesses will employ the services of a product developer or an industrial design company to be involved in the development process.

Product Development Company

A product development company typically creates new ideas or re-designs existing products collaboratively with marketing, engineering, and production manufacturing teams. A product design company will often have teams of engineers and product designers, strategists, and experienced product marketers to ensure a product’s success.

Industrial design, as a process, involves the aesthetic and ergonomic design of products. Industrial designers are like product architects who focus more on how a design will look and feel, while product engineers focus on the functionality and manufacturability of products. More art than science, industrial design determines and creates a product’s form and features, which takes place before getting into the detailed manufacturing design of a product.

The Job of a Product Development Company

Product development companies play an essential role in the growth of both small and large businesses. Product developers are responsible for transforming an idea into an invention design and improving existing products.

Product developers are employed so that a growing (or established) company can meet customers’ needs more effectively. While a product developer may work alone, a product development company usually combines design, business and engineering resources to create products that meet market and production requirements.

The job of a product development company can be summarized into;

- Market Research: involves identifying the problem and begins to conceptualize an invention design to solve the problem users are facing

- Product Proposal: putting forward an initial product specification that includes a wish list of new features of the invention idea

- Product Development: involves creating a detailed manufacturing design and converting the invention idea into a hardware prototype or software prototype

- Ongoing Product Development: the hardware prototype or software prototype is improved upon to meet the market demand, then production manufacturing and marketing can begin

Every mass-produced product, from your office chairs to electronic gadgets, cars, and home appliances, is a product of industrial design and mechanical design. However, there is no one-size-fits-all for the processes involved; the nature of the product will determine the approach used in its manufacturing.

Understanding the Concept of Industrial Design

While industrial designers are known to focus on the physical appearance and ergonomics of a product, they can also be involved in the entire development cycle of the product. Industrial design aims to improve the overall lasting value and experience of a product for the end-users.

Before the first industrial revolution of the mid-18th century to about 1830, products were hand-crafted, even at a commercial scale. As you can guess, the production processes were far longer than we have today, and they also cost significantly more.

The dawn of efficient industrialization and rapid prototyping has made it possible to streamline design, engineering, prototyping, and production manufacturing, thus, increasing the production capacity of companies while reducing the cost involved in development and production. For example, Henry

To get customers to buy newer versions of products, product developers began incentivizing customers. They did this by adding features older products lacked, such as improved ergonomics, aesthetics, and functionality, and even price point with more efficient design. Then, to speed up the product development process engineering teams turned to rapid prototyping.

What is Rapid Prototyping?

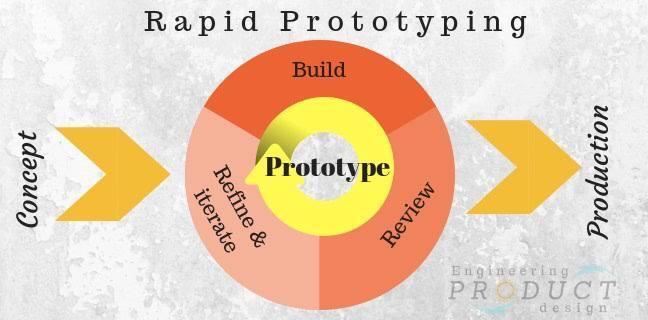

Rapid prototyping (RP) is the production of parts using manufacturing methods that are generally faster and more cost effective than traditional manufacturing processes.. These efficient and cost effective processes ensure the swift production of a design prototype.

For mobile apps and software products, this type of prototyping uses fully functional workflows and partially functional wireframes to quickly demonstrate how software will function and how users will interact with it.

RP is done in coordination with the engineering team, who uses technical documents such as the concept sketches, 3D modeling, and 2D drawings to communicate the detailed design.

Most of the time, RP is defined as the speedy manufacturing of preliminary product designs, using improved technical processes..

Rapid Prototyping Used By Companies for New Products

Steps taken through the RP process and product manufacturing include:

- Clearly Define Problems

This involves researching customer problems and defining them in an effective way. One hack to find customer problems is to research competitive and comparative products and read reviews to see what customers think of functionality and find out what real problems they have. Customers are usually honest in reviews so it’s a great source for finding customer problems. Surveying potential customers or existing customers is also a great way to learn what people need from the products they use.

- Create Effective Solutions

From analysing and understanding customer problems the product development company can define product features that will solve those problems. Then product engineers will start to flesh out prototype designs that will be used to produce professional samples in low volume before production manufacturing can begin.

- Rapid Prototyping Before Production

It is crucial to create prototypes before moving to production manufacturing. This allows product development teams to get feedback about form, fit, and function internally and directly from customers.

- Production Manufacturing and Commercialization

After prototypes have been tested and the design is finalized, the production manufacturing process can begin. This is done after the above 3 requirements are met.

Importance of Rapid Prototyping to a Product Development Company

The importance of RP cannot be overstated. Prototyped products allow for functional and structural stress tests and improvements on the 3D model.

They will also reduce the number of design and prototype iterations the engineering team will need to perform. As such, rapid prototyped products save resources and time.

RP ensures product efficacy and allows for human factors engineering to be more efficiently considered.