The product development process is often long and requires the expertise of different individuals. It takes significant planning, technical evaluations and concept verifications before converting an idea into a working product. The development cycle involves intense market research, iterative decision-making and a myriad of innovations and invention design. It implies...

Product Development Process

The almost infinite amount of products available today can make many believe that every idea turns into a successful product. However, in 1982 Booz, Allen, and Hamilton (BAH) stated that "for every seven new product ideas generated, only one succeeds." There are more failed new products, not because those ideas...

Product Development Company

Every product currently on the market started with an idea or a vision and has undergone a great deal of creativity, analysis, and strategy before it can be successfully commercialized. But with the right product development company the process can be straightford and efficient. Here we’ll explore the product development...

Multiple Iterations In The Product Development Process

Working on new product ideas is exciting and equally challenging. Innovators begin the process by identifying a market gap and brainstorming possible solutions to bridge it to improve workflows, human interactions and process efficiency. The product development process may seem linear from a general point of view. In reality, it...

Invention Design

Inventing a new product or technology is exciting! The realization and development of your product idea is done by a design team, who designs and engineers your product invention. The goal during the invention design process is to start with an idea, sometimes abstract in nature, and create a definition...

The Complete Guide To Injection Molding

Plastics have become part and parcel of our daily lives. Plastics are vital for manufacturing various consumer goods, packaging materials, pipes, prototypes, automotive, industrial, medical, aerospace, and household items. The flexibility and versatility of plastic materials make them dependable for manufacturing precision parts and can be molded into complex shapes...

Industrial Design Company

Advancement in technology has made it possible for companies to manufacture consumer products on a global scale. In addition, prototyping and automation have made it possible for large quantities of standardized products to be produced while keeping manufacturing costs low. Every mass-produced product, from your office chairs to electronic gadgets,...

Relevance Of Industrial Design

What comes to mind at the mention of mass production? Do you ponder over the numerous attempts to develop working products? It is a marvel that through the years, entrepreneurs and companies have developed robust mass production systems, delivering delightful physical products to serve the ever-growing human population. It takes...

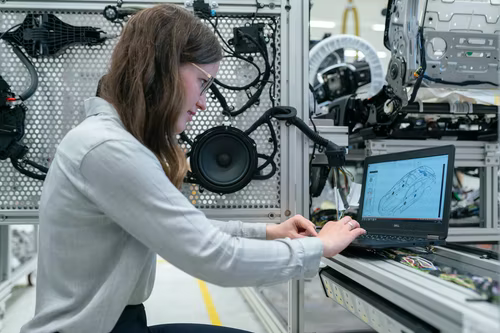

What does it take to be in design engineering?

We interact with several products daily. Each has its unique design and features that dictate its functionality. Whether it's a simple or complex design, the functional product undergoes a rigorous development process. The design engineer plays a critical role in formulating and actualizing product designs. Over time, companies and individual...

A Comprehensive Guide To CNC Machines

As the world advances, leading manufacturers, startups and individual innovators increasingly adopt automated systems to improve product development processes. Long gone are the days when product design, development and launching relied on trial and error methods. At present, everything in the product development process is automated. The future is promising...